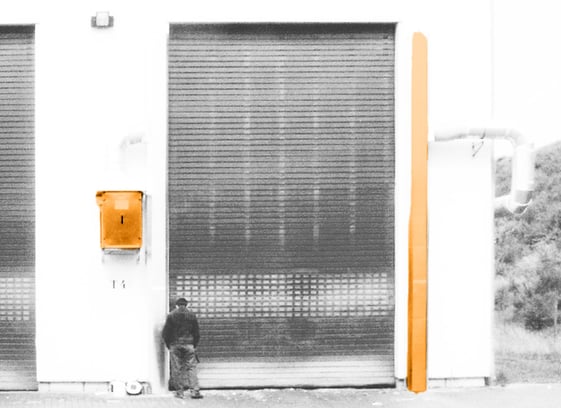

The lateral airwall is equivalent to an air lock

German legislation defines high requirements for waste treatment to avoid immissions. The 30th BImSchV[1] and the AbfAblV[2] mechanical biological waste treatment (MBT) be completely enclosed so that untreated exhaust air cannot escape.

In 2004, IGM, Ingenieurgemeinschaft Fricke und Turk, showed that an airwall encapsulates such plants just as well as air locks.

The tests were carried out at the Linkenbach MBT plant.

What is mechanical biological waste treatment?

In a mechanical biological waste treatment plant (MBT), waste from households and companies is sorted and treated.

Experimental setup

The Linkenbach MBT plant operates a delivery hall that is equipped with an extraction system to separate volatile organic compounds (VOCs). This creates negative pressure when the door is closed. Fresh air is compensated for by negative pressure louvres.

This hall has a door whose open area is 5.85 m high and 4.06 m wide. An airwall with lateral pressure modules with 14 mm wide nozzles was installed on the outside.

For specific adjustment of the airwall, the angle of the nozzles to the centre line of the door (by 15° inwards and outwards) and the output of the fans (infinitely variable up to 5,000 m3/h and 1,000 Pa pressure) can be changed.

To visually check the functionality of the air wall pilot system, artificial fog was generated in the hall and the air wall system was adjusted.

Implementation

The following tests were carried out on two days with light cloud cover and occasional showers. The wind blew at 0.2 m/s (calm) to 3 m/s (this is already clearly noticeable) mostly from the south but with clear turbulence. The outdoor temperatures were between 14°C and 19°C.

The odour was measured with the door closed and open and with the air wall on and off at five defined distances from the air wall and at different heights.

At each of these locations, 6 litres of air samples were taken across the entire width of the gate. The olfacto-metric examinations of the exhaust air samples were carried out in accordance with DIN EN 13725 of July 2003 in the laboratory of the University of Bonn, Institute for Agricultural Engineering[3].

In addition to determining the odour concentration, the test persons were asked to describe the type of odour after each sample.

Result and conclusion

With regard to the avoidance of emissions, the LWT is technically equivalent to air locks, as required by the TA-Luft[4] for encapsulation also for plants for composting, fermentation and drying of waste.

In terms of avoiding emissions, the LWT airwall is technically equivalent to airlocks as required by the TA-Luft[4] for encapsulation, also for plants for composting, fermenting and drying waste.

Furthermore, air walls are more favourable in terms of investment and operating costs. In addition, input and output processes are faster. However, the control of the air wall must be set in such a way that the air wall is built up first and only then the door is opened.“

[1] 30th Federal Immission Control Ordinance

[3] The olfactometer "Mannebeck TO8" from ECOMA GmbH was used.