Airwalls for the food industry: reliably separating temperature zones

Dealing with different temperature zones is anything but trivial in food processing companies. While ingredients need to be cooled on one side of the plant, ovens and cooking areas generate a lot of heat in other places. Separating these zones to ensure that the cold chain is maintained is an important task. Airwalls not only provide precise separation of air layers, they also allow unimpeded passage of staff and vehicles at access points.

Precise control of temperature zones

To ensure that food can be processed and still reach customers fresh, maintaining the cold chain is extremely important. Unwanted thawing of ingredients or storage that is too warm can make production batches unsaleable. At the same time, a comfortable room temperature is important for employees, and depending on the food product, cooking, baking or drying is also carried out in the factories. This creates warm zones with a lot of humidity, which must be separated from other departments in the factory.

Airwalls use a precise jet of air to separate different temperature zones.

This allows cold stores to maintain low temperatures while employees can remove goods from the cooled zones without barriers. Waste heat from ovens or baking lines is also reliably kept where it is generated.

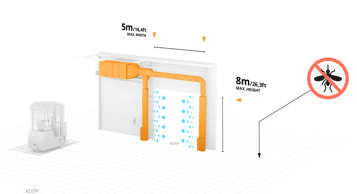

Deny access to uninvited guests

When processing food, hygiene rules are prescribed by law and are essential for the smooth running of the business. Thus, keeping insects out is important to guarantee product quality for end customers.

Airwalls reliably keep insects out without being restrictive. In contrast to partitioning such as plastic strip curtains, airwalls do not hinder operations; employees and logistics vehicles can use the passageways without losing the protective function. Especially for the food industry, we have also developed airwall systems with stainless steel air outlets that are easy to disinfect.

Sustainably reduce ancillary costs through better air conditioning

Maintaining ideal production conditions is costly. Open doors or gates ensure that heated or cooled air escapes. The result: the heating or cooling system has to work harder. This puts a strain on the equipment and results in higher energy consumption.

Efficiently sealing off entrances to buildings is therefore not only a hygiene aspect, but also a cost factor.

Our airwalls help to minimise air exchange, which sustainably reduces operating costs.

LWT's new airwall was a building block in our BRC Global Standard (BRCGS) certification. It keeps insects out, for quality in.

Maintenance Manager Coveris Bruchsal

So that the blubbing spinach and other iglo products remain energy-efficiently 'super cool' - Airwalls

Learn more in our casebooks

- Energy efficiency

- Occupational safety

What our airwalls can do:

- reduce energy consumption and thus emissions

- enable precise control of temperature zones

- seal off access points without making them impassable for employees

- increase well-being in the workplace

- are easy to keep hygienically clean